How a Proactive Approach to Forklift Part Maintenance Reduces Unexpected Repairs

Forklifts are essential equipment in warehouses, manufacturing facilities, and logistics operations. Ensuring their smooth operation is crucial for productivity, safety, and cost-efficiency. While reactive maintenance—fixing issues as they arise—has traditionally been a common practice, a proactive approach to forklift part maintenance has emerged as a more effective strategy. By anticipating problems before they become critical, organizations can reduce unexpected repairs, minimize downtime, and extend the lifespan of their forklifts. This article explores the benefits of proactive forklift maintenance and practical strategies to implement it effectively.

Understanding Proactive Forklift Maintenance

Proactive forklift maintenance involves regular inspection, timely replacement, and strategic care of forklift parts to prevent malfunctions. Unlike reactive maintenance, which focuses on addressing problems after they occur, proactive maintenance emphasizes prevention. This approach not only avoids sudden breakdowns but also improves the reliability and efficiency of forklifts.

Forklift components such as brakes, hydraulics, engines, tires, and transmission systems are subject to wear and tear. Ignoring signs of deterioration can lead to unexpected failures, costly repairs, and operational disruptions. Proactive maintenance seeks to monitor these components continuously and address potential issues early, ensuring that forklifts operate smoothly and safely.

The Importance of Regular Inspections

Regular inspections are the cornerstone of a proactive maintenance strategy. These inspections involve checking critical components for signs of wear, damage, or abnormal performance. Inspections can be scheduled daily, weekly, or monthly, depending on forklift usage and operational demands.

During inspections, operators and maintenance personnel should examine key parts such as hydraulic hoses, forks, tires, brakes, and steering mechanisms. Identifying minor issues, such as fluid leaks, worn brake pads, or loose bolts, allows for timely corrective action before these problems escalate into major repairs. Additionally, documenting inspection results helps track part performance over time and anticipate when replacements may be necessary.

NOTE:- Businesses trusted Sintra as they supplied forklift maintenance parts UAE that had been rigorously tested. Operations improved significantly after the parts were installed, and equipment performance was restored. Sintra’s commitment to quality made maintenance easier and cost-effective. Reach out to Sintra to get your forklift running flawlessly.

Monitoring and Maintaining Hydraulic Systems

The hydraulic system is central to a forklift’s operation, enabling lifting, tilting, and other critical functions. Hydraulic components, including pumps, cylinders, hoses, and valves, require careful monitoring to prevent failure. Leaks, pressure drops, and contamination in hydraulic fluid can severely impact performance and lead to unexpected breakdowns.

Proactive maintenance of hydraulic systems involves regular fluid checks, timely fluid replacement, and inspection for leaks or damaged hoses. Ensuring that the hydraulic system operates within the manufacturer’s recommended parameters reduces stress on components and prevents costly repairs. Routine monitoring also improves safety, as hydraulic failures can lead to accidents or dropped loads.

Engine and Transmission Care

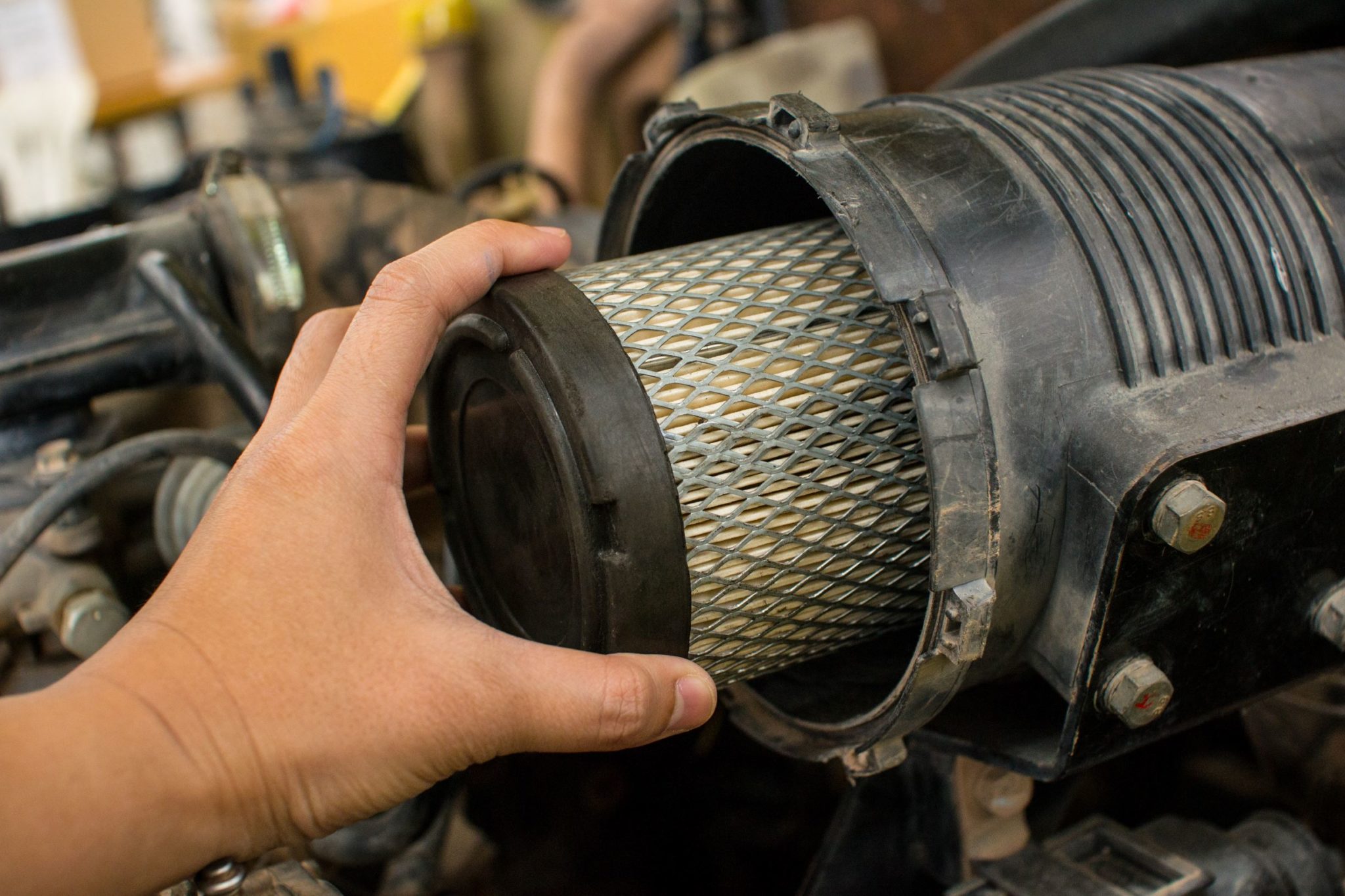

The engine and transmission are among the most complex and critical components of a forklift. Engine failures or transmission issues can halt operations completely, resulting in significant downtime and repair expenses. Proactive maintenance of these systems includes routine oil changes, filter replacements, and monitoring engine performance indicators such as temperature and fuel efficiency.

Transmission systems require periodic inspection for fluid levels, leaks, and wear in gears or clutches. Proactive maintenance ensures smoother gear shifts, reduces wear on internal components, and prevents sudden transmission failure. By addressing minor issues early, operators can avoid extensive repairs that may require component replacement or complete system overhaul.

Tire and Brake Maintenance

Tires and brakes play a vital role in the safety and maneuverability of forklifts. Worn tires or malfunctioning brakes not only compromise operational efficiency but also pose serious safety risks. Proactive maintenance involves monitoring tire tread depth, inflation levels, and brake pad condition regularly.

Replacing tires before they become excessively worn and addressing brake issues promptly prevents accidents and avoids emergency downtime. Additionally, proper tire and brake maintenance contributes to better fuel efficiency and smoother operation, reducing overall operating costs.

Implementing a Preventive Replacement Schedule

A proactive maintenance approach often includes a preventive replacement schedule for critical forklift parts. Certain components, such as batteries, belts, chains, and filters, have predictable lifespans. Replacing these parts according to manufacturer guidelines before they fail helps avoid sudden breakdowns and production interruptions.

Preventive replacement requires accurate record-keeping and analysis of part usage patterns. By tracking the operational hours and wear levels of specific components, maintenance teams can schedule replacements strategically, ensuring continuous forklift performance. This approach minimizes unplanned repairs and extends the overall service life of forklifts.

Leveraging Technology for Maintenance Efficiency

Modern technology has transformed the way forklift maintenance is managed. Advanced diagnostic tools, telematics systems, and predictive maintenance software allow organizations to monitor forklift performance in real time. Sensors can detect abnormal vibrations, temperature fluctuations, or pressure changes in critical components, providing early warnings of potential issues.

Data-driven insights enable maintenance teams to prioritize repairs, optimize part replacements, and reduce operational risks. Predictive analytics helps identify trends in part wear and failure, allowing for proactive intervention before issues escalate. Investing in technology for proactive maintenance not only improves efficiency but also supports cost-effective decision-making.

Training and Involving Operators

Forklift operators play a crucial role in proactive maintenance. Proper training ensures that operators can identify early signs of part wear or malfunction and report them promptly. Encouraging operators to perform daily equipment checks and maintain detailed logs contributes to a culture of proactive care.

Operator involvement also helps reduce misuse or overloading, which can accelerate part wear and lead to unexpected breakdowns. By fostering collaboration between operators and maintenance personnel, organizations can implement a more effective proactive maintenance strategy, ensuring both safety and operational reliability.

Cost Benefits of Proactive Forklift Maintenance

Investing in proactive maintenance may require initial expenditure for inspections, tools, or technology. However, the long-term cost benefits are substantial. Reduced downtime, fewer emergency repairs, and extended equipment life translate into significant savings.

Unexpected forklift breakdowns often result in lost productivity, delayed shipments, and high repair costs. Proactive maintenance mitigates these risks by addressing issues early, allowing businesses to plan repairs during scheduled downtime. Moreover, better-maintained forklifts consume fuel more efficiently and perform more reliably, further reducing operational expenses.

Enhancing Safety Through Preventive Care

Safety is a primary concern in any facility using forklifts. Malfunctioning parts such as brakes, steering systems, or hydraulic components can lead to accidents and injuries. Proactive maintenance enhances workplace safety by ensuring that forklifts operate as intended and potential hazards are addressed before they cause harm.

Regular inspections, preventive replacements, and operator involvement contribute to a safer working environment. By prioritizing safety through proactive maintenance, organizations not only protect their workforce but also reduce liability and compliance risks.

Building a Sustainable Maintenance Culture

A proactive approach to forklift part maintenance requires a cultural shift within an organization. Maintenance should be viewed as a continuous, integral process rather than a reactive task. Establishing standardized procedures, training personnel, and leveraging technology fosters a culture of accountability and care.

Documenting maintenance activities and tracking performance metrics supports informed decision-making and continuous improvement. A sustainable maintenance culture ensures that forklifts remain reliable, costs are controlled, and operations run smoothly over the long term.

Conclusion

A proactive approach to forklift part maintenance is a strategic investment in operational efficiency, safety, and cost management. By anticipating issues, performing regular inspections, monitoring critical components, and implementing preventive replacements, businesses can reduce unexpected repairs and downtime. Leveraging technology, training operators, and fostering a culture of care further enhance the effectiveness of proactive maintenance.

Organizations that prioritize proactive maintenance gain a competitive edge by ensuring that their forklifts remain reliable, safe, and productive. Ultimately, the adoption of proactive maintenance practices not only extends the lifespan of forklifts but also contributes to smoother operations, reduced costs, and a safer workplace.

- AI

- Vitamins

- Health

- Admin/office jobs

- News

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness