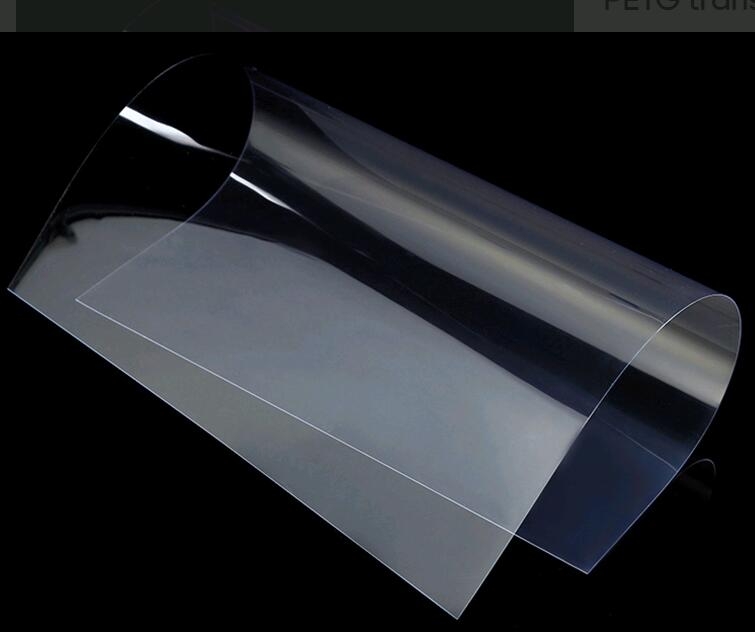

Understanding PET Clear Polyester Film

PET clear polyester film is widely used in packaging, printing, electronics, and industrial applications due to its transparency and stability. Before selecting a product, it is important to understand the basic performance requirements of the intended application, such as clarity, thickness, and mechanical strength.

Assessing Optical and Surface Properties

Clarity and surface quality are essential considerations. High-quality PET clear polyester film should offer consistent transparency without haze, bubbles, or visible defects. For printing or laminating applications, surface smoothness and uniformity help ensure good ink adhesion and an even finish. Some films are treated to improve surface energy, which can be beneficial for coating or bonding processes.

Choosing the Right Thickness and Strength

PET clear polyester film is available in a wide range of thicknesses. Thinner films are suitable for lightweight packaging or protective layers, while thicker options provide better rigidity and durability for industrial uses. Tensile strength and tear resistance should match the mechanical demands of the application to prevent deformation or damage during handling and use.

Evaluating Thermal and Chemical Resistance

Thermal stability is another important factor. PET film generally performs well across a moderate temperature range, but different grades may vary in heat resistance. For applications involving heat sealing, forming, or exposure to chemicals, it is advisable to select a film with verified resistance properties to maintain performance over time.

Considering Compliance and Application Needs

For food packaging or medical uses, compliance with relevant safety and regulatory standards is essential. Additionally, factors such as roll size, ease of processing, and compatibility with existing equipment should be reviewed to ensure smooth production.

https://www.zhongshengnewmaterial.com/product/petg-sheet-film/petg-transparent-film-sheet-for-medicine-package.html

PETG is non-toxic and can be used for packaging of food, medicine and medical devices.

Advantages of PETG:

Durable

High transparency

Good luster

High flexibility

- AI

- Vitamins

- Health

- Admin/office jobs

- News

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness