Processing Methods of Bumper Molding for Cars

Car bumper moldings are essential components designed to enhance safety, aesthetics, and aerodynamics. Producing high-quality bumper moldings requires precise manufacturing techniques and careful material handling. Various processing methods are used depending on the material, design complexity, and production volume.

Injection Molding

Injection molding is one of the most common methods for producing plastic bumper moldings. In this process, molten plastic is injected into a mold cavity that defines the bumper’s shape. Once cooled, the solidified bumper is ejected from the mold. This method allows for high precision, repeatability, and the ability to produce complex shapes with integrated features such as mounting points or slots.

Compression Molding

Compression molding is primarily used for thermosetting plastics and reinforced materials. In this process, a preheated material is placed into an open mold cavity, and pressure is applied to shape it. Compression molding is particularly suitable for producing strong, durable bumper moldings that require reinforcement or added rigidity.

Extrusion and Trimming

For certain bumper components, extrusion may be used to create continuous profiles, which are later cut and trimmed to the required dimensions. Extruded parts can then undergo secondary operations such as drilling, welding, or painting. This method is often used for bumper trims, protective strips, or decorative elements.

Finishing and Surface Treatment

After molding, bumper parts undergo finishing processes, including sanding, trimming, painting, and coating. Surface treatments improve aesthetics, UV resistance, and impact resistance. Quality control inspections ensure that dimensions, surface quality, and fit meet automotive standards.

https://www.bumpermould.net/product/bumper-mould/plastic-front-bumper-for-bmw-x1.html

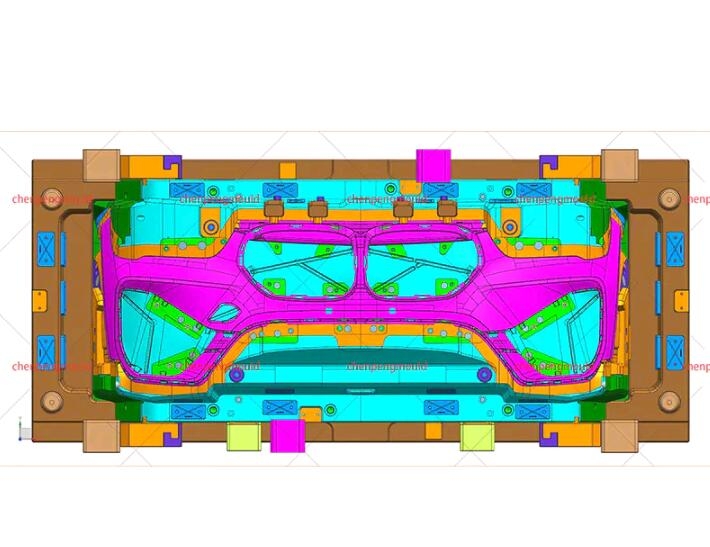

Mould Name BMW X1 Car Front Bumper Chin Mould

Material PP+EPDM

Bumper Size 1900*610*560mm

Steel For Cavity &. Core P20

Mould Base C45

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

- AI

- Vitamins

- Health

- Admin/office jobs

- News

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness