How 10 Gallon Environmental Tank Works With Jatco Shell And Tube Systems

Across the ultramodern energy sector, the need for compact storehouse, advanced separation, and effective waste- handling results continues to grow. Within drilling, product, transportation, and recycling surroundings, drivers are decreasingly dependent on tools that ameliorate environmental safety without decelerating workflows. This is where the 10 gallon environmental tank has surfaced as one of the most precious pieces of constraint outfit for maintaining nonsupervisory norms and functional perfection in colorful settings. When paired with high- performance heat- exchange technologies like the jatco shell and tube, companies achieve elevated control over temperature-dependent separation processes, vapor reduction, and fluid stability. These technologies round broader systems — similar as impurity forestallment modules, the btex eliminator system, vapor prisoner units, and slip mitigation outfit — to form a dependable foundation for ultramodern environmental operation strategies. As demand grows for stronger sustainability practices and practical constraint results, the integration of tanks, exchangers, covering systems, and filtration technology shapes a cleaner, safer future for the energy assiduity.

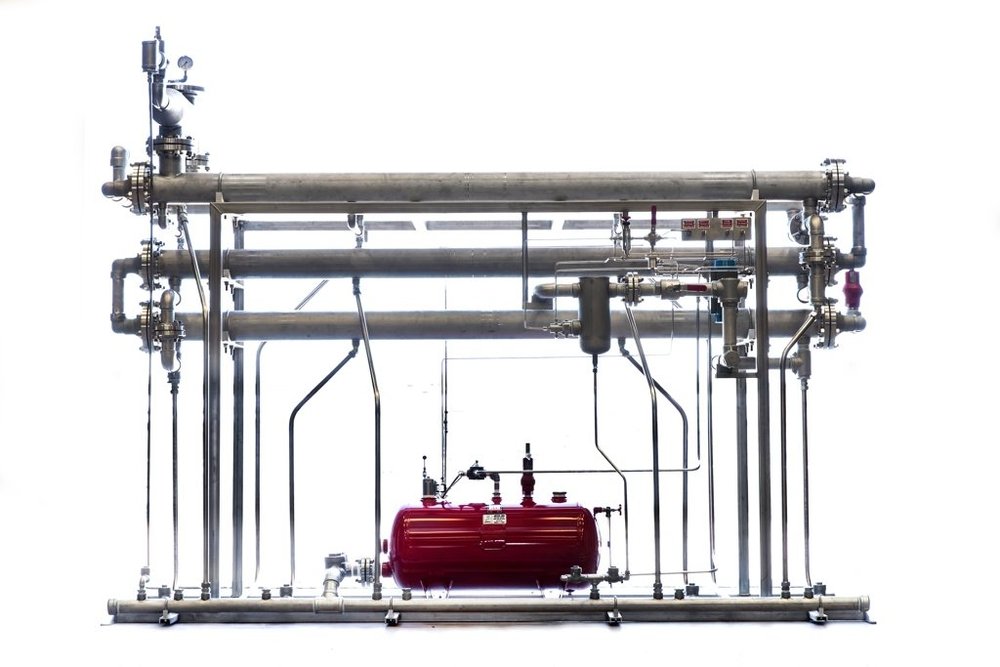

The Essential part of Small- Scale Containment in Large- Scale Operations

Indeed though the capacity is modest, the 10 gallon environmental tank is extensively considered an essential tool for maintaining environmental integrity during high- volume field operations. Its compact size makes it ideal for landing sample volumes, separating fluids, controlling vapor affair, and supporting slip- response systems. In resemblant, energy spots decreasingly emplace the jatco shell and tube technology to regulate heat transfer, stabilize hydrocarbons, and ameliorate overall fluid processing delicacy. Working together, these tools enhance on- point effectiveness, reduce waste, and support everything from routine examinations to ferociousmulti-stage separation conditions. Drivers also combine these systems with results similar as jatco environmental tanks and modular pollution- control outfit to meet prospects for environmental compliance for oil painting and gas operations. As the assiduity shifts toward further adaptive constraint strategies, small tanks and effective exchangers play a critical part in maintaining functional trustability and sustainability.

Strengthening Environmental Compliance Through Better Temperature and Fluid Control

As regulations continue to strain, environmental compliance hinges on further than simple constraint — spots must demonstrate proper fluid treatment, heat operation, vapor control, and waste- handling practices. The 10 gallon environmental tank helps achieve these pretensions by maintaining controlled surroundings for fluids before slice, disposal, or processing. When paired with a jatco shell and tube exchanger, drivers gain precise temperature control demanded for fluid separation, condensate stability, and vapor mitigation. These systems work seamlessly with air- quality operation tools, vapor recovery units, and the btex eliminator system to reduce unpredictable emigrations and cover original ecosystems. With controllers placing lesser emphasis on environmental compliance for oil painting and gas, companies must use compact yet high- performance systems that streamline environmental reporting and insure accurate control of dangerous composites. The pairing of tanks and exchangers supports these sweats while buttressing broader sustainability commitments.

Improving Pollution Control and Reducing Environmental Liability

Environmental liability is one of the most significant fiscal pitfalls for oil painting and gas drivers. A single slip, leak, or vapor release can affect in immense forfeitures, legal action, and long- term ecological damage. The 10 gallon environmental tank plays a pivotal part in precluding similar events by serving as a first line of constraint for fluids and vapors produced during testing, drilling, or transport operations. Meanwhile, the jatco shell and tube exchanger improves effectiveness during thermal processing, allowing drivers to stabilize fluids and reduce vapor conformation before emigrations do. Working alongside pollution control outfit for oil painting and gas, these systems limit the release of dangerous composites into soil, air, or water. Thismulti-layered approach enhances the environmental stability of on- point operations while reducing pitfalls associated with unpredictable hydrocarbon fusions. Given the adding prospects girding environmental sustainability in oil painting and gas assiduity practices, companies must calculate on stronger, more advanced pollution- control integrations to maintain responsible operations.

Supporting Water Protection and Reducing impurity pitfalls

Water protection remains one of the most critical enterprises within oil painting and gas operations. indecorous fluid running or hamstrung heat control can pollute groundwater, gutters, and washes. The 10 gallon environmental tank ensures constraint of waste fluids, product remainders, and chemical by- products, thereby precluding accidental tumbles. When this tank is part of a system that also includes a jatco shell and tube exchanger, drivers gain fresh stability by controlling fluid temperature during separation processes, precluding unwanted responses or inordinate vapor pressure. These concerted technologies round advanced systems similar as jatco tanks, above- ground constraint results, and wastewater filtration tools, creating a stronger defense against water pollution. This concentrated approach supports assiduity prospects for environmental sustainability in oil painting and gas assiduity operations by guarding natural coffers and icing responsible fluid operation from font to distribution installations.

Optimizing functional Safety Through Better Containment and Temperature Regulation

Safety is central to any energy- producing operation. outfit failures, pressure imbalances, and impurity events hang both labor force and the terrain. The 10 gallon environmental tank reinforces safer operations by reducing exposure to chemicals, hydrocarbons, and vapors during point exertion. Its integration with the jatco shell and tube exchanger further enhances safety by stabilizing fluids and minimizing thermal pitfalls associated with shifting temperatures. For installations operating BTEX- producing outfit, the btex eliminator system is generally paired with small tanks to enhance vapor control. When stationed strategically, these systems reduce plant exposure to dangerous composites, strengthen incident- forestallment strategies, and insure compliance with safety regulations. The commitment to defensive design and enhanced point safety reinforces the broader need for Environmental results for oil painting and Gas that support safe, effective, and environmentally conscious design prosecution.

Enhancing Sustainability Through Better Temperature- Directed Environmental Processing

Sustainability sweats extend beyond emigrations reduction — they bear smarter approaches to fluid operation, heat control, and waste minimization. By integrating the 10 gallon environmental tank with advanced thermal systems similar as the jatco shell and tube, drivers gain lesser effectiveness inmulti-phase separation, condensate recovery, and low- emigration processing. These tools help companies streamline pollution- control workflows while lowering energy consumption and reducing chemical waste. When used alongside systems like jatco environmental tanks, vapor recovery outfit, andeco-driven filtration modules, compact tanks and shell- and- tube exchangers significantly boost environmental sustainability in oil painting and gas assiduity operations. They also help reduce the footmark of drilling and product conditioning, buttressing the assiduity's commitment to long- term resource preservation. Through these combined technologies, sustainability becomes attainable at both small and large functional scales.

Integrating Containment and Heat- Exchange Systems Into Modern Energy structure

As digital metamorphosis accelerates within the energy sector, tools similar as the 10 gallon environmental tank are decreasingly integrated into automated systems that support remote monitoring and real- time environmental reporting. Paired with a jatco shell and tube unit, these tanks give stable performance in data- driven operations where temperature control, leak monitoring, and pressure operation are essential. Their comity with ultramodern instrumentation enhances the effectiveness of environmental compliance programs and enables drivers to acclimate environmental strategies grounded on real- time data. These systems also work effectively with modular pollution control outfit for oil painting and gas, vapor- operation suites, and filtration units, creating unified environmental strategies across disquisition, product, and refining installations. The community between constraint and heat- exchange technologies forms a foundation of future-ready energy structure.

Expanding Environmental Benefits Across Midstream and Downstream Sectors

Midstream and downstream operations deal with significant volumes of reused hydrocarbons, chemical complements, and hotted fluids. The 10 gallon environmental tank provides dependable constraint for slice, testing, waste collection, and separation conditioning within these stages of the energy lifecycle. Meanwhile, the jatco shell and tube exchanger enables precise thermal control during refining, transport medication, and storehouse stabilization workflows. When used together, these tools grease safer and further environmentally responsible running of hydrocarbons, contributing to advanced performance norms across outstations, channels, storehouse capitals, and processing shops. These systems round advanced constraint results similar as jatco tanks, waste- sluice filtration units, and vapor collection modules designed to support environmental compliance for oil painting and gas far beyond the font. Their combined environmental benefits strengthen sustainability practices throughout the entire assiduity force chain.

Supporting BTEX and VOC Reduction Across All functional Areas

Effective BTEX and VOC operation continues to be one of the assiduity's loftiest precedences. By exercising a 10 gallon environmental tank, drivers can insulate fluids and vapors containing benzene, toluene, ethylbenzene, and xylene before they spread into the terrain. When combined with a jatco shell and tube exchanger, temperature regulation becomes more precise, perfecting vapor stabilization and reducing emigrations at the source. This binary approach is frequently supported further by integrating the btex eliminator system, which captures and neutralizes dangerous vapors before release. As environmental prospects increase and companies commit to bettered environmental sustainability in oil painting and gas assiduity practices, these technologies produce a important result that ensures cleaner, safer, and more responsible operations. Compounded with other pollution- control systems, they significantly minimize air pollution and cover environmental quality.

Unborn Trends and Evolving Environmental norms in Energy Operations

The energy sector is shifting toward stricter regulations, advanced monitoring prospects, and environmentally intelligent design. As this elaboration continues, tools similar as the 10 gallon environmental tank will play an decreasingly important part in sustainable operations. Likewise, the jatco shell and tube exchanger will continue to support more precise temperature operation within fluid- handling operations across drilling, product, and refining. These systems will come indeed more essential as drivers borrow advanced environmental robotization, integrate discovery detectors, and expand pollution- mitigation strategies. As further companies strengthen their commitments to Environmental results for oil painting and Gas, the integration of small- scale constraint and high- perfection heat- exchange systems will accelerate environmental progress across the assiduity. These inventions form the backbone of both current and unborn sustainability fabrics.

Conclusion Moving Toward a Cleaner, Compliance- Driven Future

With environmental regulations tensing and sustainability pressures adding, the 10 gallon environmental tank and the jatco shell and tube exchanger have come vital tools for perfecting effectiveness, reducing waste, and precluding pollution across all stages of energy operations. Their combined value helps companies maintain responsible workflows, reduce emigrations, and cover natural coffers. For associations seeking reliable results backed by engineering excellence, high- performance constraint, and sustainable design, Jatco Inc remains a trusted name in the development of ultramodern environmental technologies.

FAQs

How does a 10 gallon environmental tank ameliorate functional safety?

It provides controlled constraint for fluids and vapors, reducing pitfalls of tumbles, exposure, and environmental impurity.

What's the part of a shell and tube exchanger in oil painting and gas?

It regulates temperature during fluid processing, improves separation effectiveness, and reduces vapor emigrations.

Can I use a small tank for BTEX reduction?

Yes, when paired with BTEX mitigation systems, small tanks enhance vapor control.

How do these systems support nonsupervisory compliance?

They ameliorate constraint delicacy, temperature control, waste running, and covering all essential for compliance.

Are small- capacity tanks useful in large spots?

Absolutely. They give perfection running, sample constraint, and controlled separation in areas where large systems are not practical.

- AI

- Vitamins

- Health

- Admin/office jobs

- News

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness