Efficient Distribution Management for Customer Satisfaction

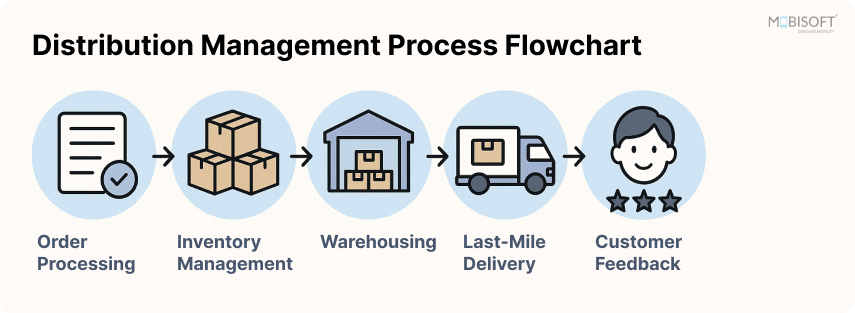

Think about the last time you placed an order online. Pretty smooth, right? But behind that simple click is a complex journey that's supply chain distribution in action. And it's evolving every day. With expanding markets and rising customer expectations, businesses are feeling the heat to deliver faster, more accurately, and without a hitch. Whether you're in retail or handling cold chain goods, the pressure is the same.

The truth is, old school methods just don't cut it anymore. Manually tracking orders slows things down. Paper-based systems create confusion. When teams aren't connected, small missteps turn into costly delays. And then there's the last-mile delivery optimization challenge, where most of the chaos happens, and issues like pilferage that quietly chip away at profits.

This is where automated distribution systems and intelligent tools step up. With the right tech, distributors can see what's happening in real time, automate the repetitive stuff, and make quicker decisions. Route planning gets smarter. Mobile tracking keeps everyone in the loop. And the entire distribution management system (DMS) runs smoother.

The result? Less stress for managers, more customer satisfaction in logistics.

Let's dive into how tech is transforming the way we move goods, what transportation logistics industry trends are leading the change, and how efficient distribution management and Transportation Management Systems (TMS) are helping businesses stay ahead.

The Key Challenges in Modern Distribution Management

Complex Multi-Location Inventory Coordination

Distributors often operate across multiple warehouses, each catering to different geographies and customer segments. Managing this landscape without a unified distribution management system (DMS) is like trying to solve a puzzle with missing pieces.

Stock imbalances are common, with overstock in one region and shortages in another. This leads to delayed deliveries, increased carrying costs, and missed sales. Without centralized visibility, it's nearly impossible to optimize replenishment or align stock with shifting customer demand.

Seasonal trends, regional preferences, and unpredictable order volumes add further complexity. Manual methods and outdated tools simply can't keep up. Businesses need intelligent systems that offer real-time updates, analyze patterns, and automatically balance stock across locations. This not only prevents waste but also ensures that customers always find what they need when and where they need it through smart inventory management practices.

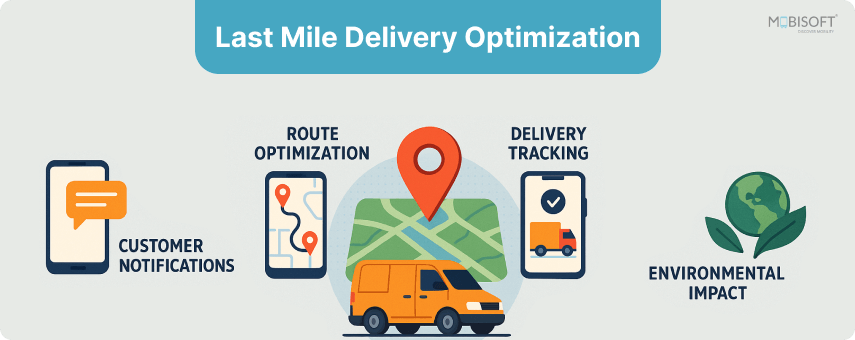

Managing Last Mile Delivery Efficiently

The last mile often feels like the shortest stretch, but it carries the most weight. It is the most critical and the most unpredictable part of the order fulfillment process. More importantly, it is the part your customers see and experience firsthand.

One late delivery or a missed time slot can do more harm to your brand image than any amount of behind-the-scenes efficiency. Customers remember the delivery moment. That is where expectations meet reality.

The last mile is complex for many reasons; traffic, delivery density, and even weather can create delays. Add rising expectations like same-day or next-day delivery, and the pressure to perform becomes even higher.

To stay ahead, businesses need flexible systems that adjust in real time. Tools like GPS tracking, automated scheduling, and intelligent route planning help teams move faster and smarter. These tools reduce fuel usage, improve success rates, and shorten delivery windows.

Most importantly, they help businesses deliver on their promise. Orders arrive on time. Customers stay happy. And the brand earns their trust again with every delivery, thanks to strong last-mile delivery optimization strategies.

For businesses looking to refine their logistics, a transportation management system for distributors can bring centralized control and efficiency to every stage of the delivery process.

Handling Returns and Reverse Logistics

Returns are no longer just a back-office task. They have become a key part of the customer experience. Whether the reason is a damaged item, a wrong order, or just a change of mind, how the return is handled matters.

A poor return experience causes delays and frustration. It can damage customer trust and create extra work for warehouse teams. Without a structured process in place, reverse logistics can quickly become messy and expensive.

A strong returns strategy makes all the difference. It includes simple workflows, quick processing, and smart routing of items back into the system. Whether the product is restocked, repaired, or recycled, fast resolution builds confidence.

Advanced systems also use return data to highlight recurring issues. For example, they can flag damaged packaging or product defects. This gives businesses a chance to fix problems at the source and reduce returns over time.

When returns are handled well, customers feel supported. That support turns into long-term loyalty.

Keeping Track of Order Status and Shipment Visibility

Customers today want more than fast delivery; they want full transparency. “Where is my order?” is no longer a question that customer support should answer manually.

Without real-time shipment visibility, internal teams waste hours tracking down information. Customers grow frustrated when updates are vague or nonexistent. Delays, misrouted deliveries, or lost packages go unnoticed until it's too late.

Digital platforms with live tracking, automated alerts, and digital proof of delivery bring transparency to every stakeholder. Customers stay informed from checkout to doorstep. Businesses can identify issues proactively, keeping service levels high and support calls low. In B2B scenarios, this level of visibility becomes a key reason clients choose and stick with a logistics partner.

Ensuring Compliance with Regional Regulations

Distribution across regions means dealing with a web of regulations, everything from local taxes to transport permits and safety standards. Missing a step can mean shipment delays, fines, or even legal trouble.

Manual compliance tracking is risky and time-consuming. Each region has its own rules, formats, and documentation. One overlooked form or expired license can stall an entire truckload.

Supply chain management best practices now demand automated compliance systems that make it easier to stay on the right side of the law. They auto-generate required documents like e-way bills, tax invoices, and permits based on destination and cargo. This reduces manual effort, ensures accuracy, and speeds up border checks and inspections. For sensitive goods like chemicals, pharmaceuticals, or food, compliance is not just good practice, it's critical.

How Smart Distribution Management Solves These Problems

Centralized Order Tracking

Today's distribution management system (DMS) platforms offer end-to-end visibility of orders. From the point of order being placed by the customer to the destination point, each step is monitored.

Operations personnel are given the ability to quickly determine order status, delays, and delivery confirmations. Customers are given visibility to self service portals, allowing them to track their orders in real-time and diminishing support requests and overall satisfaction.

This transparency enables teams to be held accountable and builds trust with the customers. It also speeds up problem solving and enhances communication between departments within.

Optimized Route Planning

Legacy routing is static and wasteful. Intelligent route planning software employs historical patterns, artificial intelligence, and real-time information to create dynamic, optimized routes.

They take into consideration delivery speed, road conditions, availability of drivers, and even fuel consumption. Routes are optimized in real-time so that deliveries are efficient and quick.

In retail or produce industries, where timing is everything, route planning enabled by the best transportation management systems plays a vital role in logistics optimization. It saves not only money but also product quality and shelf life. Reduced wait time translates into happier customers and less operational stress.

Learn More: https://mobisoftinfotech.com/resources/blog/transportation-logistics/efficient-distribution-management-customer-satisfaction

- AI

- Vitamins

- Health

- Admin/office jobs

- News

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness