How Can Product Design and Prototyping Improve Manufacturing Readiness?

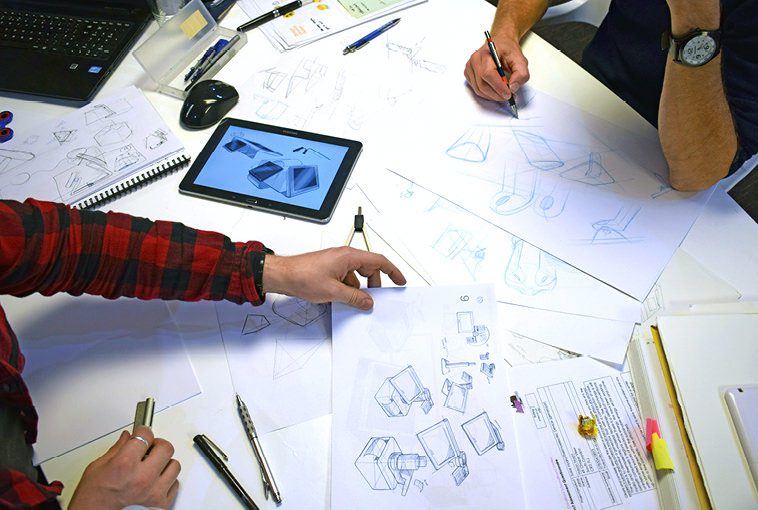

Manufacturing readiness rarely happens by accident. It is shaped early, often long before machines are turned on. Product Design and Prototyping sit at the center of that process, quietly deciding whether production will flow or fracture. When ideas are translated with intent, risk drops and confidence rises. This article explores how thoughtful design choices and realistic prototypes prepare products for real-world manufacturing, not just conceptual success, while keeping timelines, costs, and teams aligned.

Designing With Manufacturing Constraints in Mind

Strong manufacturing readiness starts when design teams acknowledge real factory limits. Materials, tolerances, tooling access, and assembly logic should influence early decisions. Ignoring these realities may create beautiful concepts that stall later. Designers who collaborate with engineers early reduce friction and redesign cycles. Small adjustments at this stage save months downstream. Manufacturing-aware design helps ensure that what looks good on screen can actually be built, scaled, and repeated without chaos or constant firefighting.

Manufacturers often remember projects where one ignored constraint caused endless revisions. Those stories rarely fade. They reinforce why early discipline matters.

Prototyping as a Reality Check, Not a Showcase

Prototypes are not meant to impress stakeholders alone. They exist to expose weaknesses before production does. Early-stage models reveal ergonomic issues, structural gaps, and material behavior under stress. Even rough prototypes can answer critical questions. Can it be assembled easily? Does it fail in predictable ways? Prototyping reframes assumptions into evidence. It replaces optimism with insight. This process builds manufacturing confidence by letting teams learn fast, fail small, and adjust without burning large budgets.

Skipping this step often leads to expensive lessons later. Few teams enjoy those lessons.

Reducing Costly Iterations Before Production

Every change made after tooling begins costs more. Product design paired with iterative prototyping shifts those changes earlier, when they are cheaper and faster. Teams can refine dimensions, simplify parts, and eliminate unnecessary complexity. This early tuning prevents cascading changes during production ramp-up. Manufacturing readiness improves when designs reach the floor already tested and refined. The result is fewer engineering change orders, less downtime, and smoother communication across departments that rely on stability.

The hidden value here is morale. Fewer surprises mean calmer teams and better focus.

Aligning Cross-Functional Teams Through Shared Artifacts

Prototypes act as a shared language between design, engineering, quality, and manufacturing teams. A physical or functional model removes ambiguity that drawings often leave behind. Everyone can see the same object, touch it, and question it. This alignment reduces misinterpretation and assumptions. Manufacturing readiness improves when teams rally around the same reference point. Decisions become faster. Disagreements become more productive. Clarity replaces speculation, which is essential when scaling from concept to production reality.

Conversations grounded in something tangible tend to move forward faster.

Testing Materials and Processes Under Real Conditions

Not all accoutrements bear the same once gauged . Prototyping allows brigades to test homestretches, continuity, and supplier variability beforehand. It also exposes process challenges like welding deformation, molding loss, or assembly fatigue. These perceptivity guides smarter sourcing and process selection. Manufacturing readiness improves when material choices are validated beyond proposition. Real- world testing prevents late- stage negotiations that disrupt schedules and budgets, especially when force chains are formerly under pressure.

Experience shows that materials rarely fail politely. They fail unexpectedly.

Improving Quality Planning Before Full Production

Quality is easier to plan when design intent is clear and proven. Prototypes help define inspection points, tolerances, and acceptable variation. They allow quality teams to build control plans based on reality, not assumptions. Manufacturing readiness strengthens when quality considerations are baked in early. This reduces scrap, rework, and customer complaints later. A prototype-tested design sets realistic expectations for what “good” looks like on the production line.

Quality teams appreciate being involved early. It saves everyone time later.

Supporting Scalable Assembly and Automation Decisions

A product that works in small quantities may struggle at scale. Prototyping reveals whether assembly steps are repeatable or awkward. It helps identify opportunities for automation or modular assembly. Manufacturing readiness depends on these insights. Designers can adjust layouts to reduce manual handling or improve cycle times. Prototypes expose bottlenecks before they harden into production constraints, allowing smarter investment decisions in tooling and automation strategies.

Scaling is rarely linear. Prototypes make that clear early.

Validating Compliance and Regulatory Requirements Early

Many products must meet regulatory standards before entering the market. Prototypes allow early testing against safety, environmental, and industry-specific requirements. Discovering compliance gaps late can derail production plans entirely. Manufacturing readiness improves when regulatory considerations influence design from the start. Early validation reduces the risk of failed certifications or redesigns that delay launches. It also builds trust with partners who depend on predictable timelines.

Regulators are not impressed by excuses. Preparation matters.

Strengthening Supplier Collaboration and Feedback

Suppliers play a critical role in manufacturing success. Prototypes give them something concrete to evaluate and improve. They can suggest alternative materials, processes, or tolerances based on experience. This collaboration improves manufacturability and cost control. Manufacturing readiness grows when suppliers are engaged early rather than handed final drawings. Prototypes invite practical feedback that strengthens the entire production ecosystem.

Suppliers often see problems internal teams miss. Listening pays off.

Building Confidence for Production Ramp-Up

Perhaps the most overlooked benefit is confidence. Teams that have designed thoughtfully and prototyped thoroughly approach production with fewer unknowns. Manufacturing readiness is as much psychological as technical. When risks are identified and addressed early, decision-making becomes calmer. Ramp-up phases feel manageable instead of frantic. Prototypes provide proof that the product can survive real conditions, not just theoretical ones.

Confidence changes how teams respond when issues do arise.

Conclusion

Manufacturing readiness is not achieved at the factory door. It is built through disciplined thinking, tested assumptions, and early collaboration. Product Design and Prototyping turn ideas into manufacturable realities by reducing risk, aligning teams, and validating decisions early. When done right, Product Design becomes a strategic tool, not just a creative step, ensuring smoother launches and more resilient production outcomes.

- AI

- Vitamins

- Health

- Admin/office jobs

- News

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness